Aluminium Edelstahl Senkkopf Öffnung Typ Saugmittel:

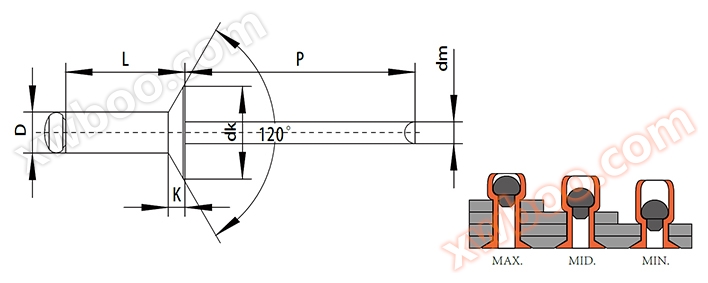

Aluminium-Edelstahl-Senkkopf-Öffnung-Typ-Pumpkernetten sind Pumpkernetten aus Aluminium mit 120 Grad-Senkkopf und Edelstahl-Nagelkern.

Eigenschaften:

1, breiter Nietbereich;

2, hohe Festigkeit, niedrige Kosten;

3. hohe Installationseffizienz;

4, die allgemeinen Befestigungsanforderungen erfüllen, ein breites Anwendungsspektrum;

5, hohe Korrosionsbeständigkeit;

6, glatte Oberfläche nach dem Nieten.

Anwendung:

Aluminium-Edelstahl-Sink-Kern-Nieten eignen sich für Karton, Holzplatte, Sperrplatte, Glasfaserplatte, Asbestplatte, Gummiplatte, Eisenplatte, Eisenhülle, Aluminiumprofile, Aluminiumlegierungsplatten, Werkzeugschilder und andere Verbindungsbefestigungen; Weit verbreitet in der Dekoration von Gebäuden, Dekoration, Schiffe, Autos, Züge, Luftfahrt, Elektronik, mechanische Stahlkonstruktionen und andere Nietbereiche; Besonders geeignet für korrosive Umgebungen.

Parameter:

| D | L | Nietbereich | Produktcode | dk | k | dm | p | Widerstand gegen Zug | Schnittschutz | ||

| 2.4 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 6.0 | 2.0~3.5 | A2BC-24060 | 4.8 [+0/-0.6] | 0.8 | 1.45 | 27 | 350 | 250 | ||

| [+0.08/-0.10] | 8 | 3.0~5.5 | A2BC-24080 | |||||||

| 10.0 | 5.0~7.5 | A2BC-24100 | ||||||||

| 2.5mm | - | - | ||||||||

| 3.0 | 6.0 | 2.0~3.0 | A2BC-30060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 550 | 400 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A2BC-30080 | |||||||

| 10.0 | 4.5~7.0 | A2BC-30100 | ||||||||

| 3.1mm | 12 | 6.5~9.0 | A2BC-30120 | |||||||

| 3.2 | 6.0 | 2.0~3.0 | A2BC-32060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 700 | 500 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A2BC-32080 | |||||||

| 10.0 | 4.5~7.0 | A2BC-32100 | ||||||||

| 3.3mm | 12 | 6.5~9.0 | A2BC-32120 | |||||||

| 14.0 | 8.0~11.0 | A2BC-32140 | ||||||||

| 16 | 9.0~12.5 | A2BC-32160 | ||||||||

| 4.0 | 6.0 | 1.5~2.5 | A2BC-40060 | 7.8 [+0/-0.8] | 1.3 | 2.2 | 27 | 1200 | 850 | |

| [+0.08/-0.15] | 8.0 | 1.5~4.0 | A2BC-40080 | |||||||

| 10.0 | 3.5~6.0 | A2BC-40100 | ||||||||

| 4.1mm | 12.0 | 5.5~8.0 | A2BC-40120 | |||||||

| 14.0 | 7.5~10.0 | A2BC-40140 | ||||||||

| 16.0 | 9.5~12.0 | A2BC-40160 | ||||||||

| 18.0 | 10.0~13.5 | A2BC-40180 | ||||||||

| 20.0 | 11.0~15.5 | A2BC-40200 | ||||||||

| 4.8 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 8.0 | 2.0~3.5 | A2BC-48080 | 9.0 [+0/-0.5] | 1.5 | 2.7 | 27 | 1700 | 1200 | ||

| 10.0 | 3.0~5.5 | A2BC-48100 | ||||||||

| [+0.08/-0.15] | 12.0 | 5.0~7.5 | A2BC-48120 | |||||||

| 14.0 | 7.0~9.5 | A2BC-48140 | ||||||||

| 4.9mm | 16.0 | 8.0~11.5 | A2BC-48160 | |||||||

| 18.0 | 10.0~13.5 | A2BC-48180 | ||||||||

| 20.0 | 11.0~15.0 | A2BC-48200 | ||||||||

| 25.0 | 15.0~19.0 | A2BC-48250 | ||||||||

| 30.0 | 19.0~24.0 | A2BC-48300 | ||||||||

| 5.0 | 8.0 | 2.0~3.5 | A2BC-50080 | 9.3 [+0/-0.8] | 1.6 | 2.7 | 27 | 2000 | 1400 | |

| 10.0 | 3.0~5.5 | A2BC-50100 | ||||||||

| [+0.08/-0.15] | 12.0 | 5.0~7.5 | A2BC-50120 | |||||||

| 14.0 | 7.0~9.5 | A2BC-50140 | ||||||||

| 5.1mm | 16.0 | 8.0~11.5 | A2BC-50160 | |||||||

| 18.0 | 10.0~13.5 | A2BC-50180 | ||||||||

| 20.0 | 11.0~15.0 | A2BC-50200 | ||||||||

| 25.0 | 15.0~19.0 | A2BC-50250 | ||||||||

| 30.0 | 19.0~24.0 | A2BC-50300 | ||||||||

| 6.0 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 8.0 | 2.0~2.5 | A2BC-60080 | 11.0 [+0/-0.7] | 1.9 [+0/-0.4] | 3.3 | 31 | 3000 | 2100 | ||

| [+0.08/-0.15] | 10.0 | 2.0~4.5 | A2BC-60100 | |||||||

| 12.0 | 3.0~6.0 | A2BC-60120 | ||||||||

| 6.1mm | 14.0 | 5.0~8.0 | A2BC-60140 | |||||||

| 16.0 | 7.0~10.0 | A2BC-60160 | ||||||||

| 18.0 | 9.0~12.0 | A2BC-60180 | ||||||||

| 22.0 | 13.0~16.0 | A2BC-60220 | ||||||||

| 26.0 | 17.0~20.0 | A2BC-60260 | ||||||||

| 30.0 | 20.0~23.5 | A2BC-60300 | ||||||||

| 33.0 | 23.0~26.5 | A2BC-60330 | ||||||||

| 35.0 | 23.5~28.0 | A2BC-60350 | ||||||||

| 6.4 | 10.0 | 2.5~4.0 | A2BC-64100 | 12.0 [+0/-0.7] | 2.0 [+0/-0.5] | 3.7 | 31 | 3150 | 2200 | |

| 12.0 | 3.5~6.0 | A2BC-64120 | ||||||||

| [+0.08/-0.15] | 15.0 | 6.0~8.5 | A2BC-64150 | |||||||

| 18.0 | 9.0~11.5 | A2BC-64180 | ||||||||

| 6.5mm | 22.0 | 11.5~15.5 | A2BC-64220 | |||||||

| 26.0 | 15.0~19.0 | A2BC-64260 | ||||||||

| 30.0 | 18.0~23.0 | A2BC-64300 | ||||||||

| 33.0 | 20.0~25.5 | A2BC-64330 | ||||||||

| D | L | Nietbereich | Produktcode | dk | k | dm | p | Widerstand gegen Zug | Schnittschutz | ||

| 2.4 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| [+0.08/-0.10] | 6.0 | 2.0~3.5 | A3BC-24060 | 4.8 [+0/-0.6] | 0.8 | 1.45 | 27 | 355 | 315 | |

| 8 | 3.0~5.5 | A3BC-24080 | ||||||||

| 2.5mm | 10.0 | 5.0~7.5 | A3BC-24100 | |||||||

| 3.0 | 6.0 | 2.0~3.0 | A3BC-30060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 810 | 550 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A3BC-30080 | |||||||

| 10.0 | 4.5~7.0 | A3BC-30100 | ||||||||

| 3.1mm | 12 | 6.5~9.0 | A3BC-30120 | |||||||

| 3.2 | 6.0 | 2.0~3.0 | A3BC-32060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 980 | 750 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A3BC-32080 | |||||||

| 10.0 | 4.5~7.0 | A3BC-32100 | ||||||||

| 3.3mm | 12 | 6.5~9.0 | A3BC-32120 | |||||||

| 14.0 | 8.0~11.0 | A3BC-32140 | ||||||||

| 16 | 9.0~12.5 | A3BC-32160 | ||||||||

| 4.0 | 6.0 | 1.5~2.5 | A3BC-40060 | 7.8 [+0/-0.8] | 1.3 | 2.2 | 27 | 1600 | 1200 | |

| [+0.08/-0.15] | 8.0 | 1.5~4.0 | A3BC-40080 | |||||||

| 10.0 | 3.5~6.0 | A3BC-40100 | ||||||||

| 4.1mm | 12.0 | 5.5~8.0 | A3BC-40120 | |||||||

| 14.0 | 7.5~10.0 | A3BC-40140 | ||||||||

| 16.0 | 9.5~12.0 | A3BC-40160 | ||||||||

| 18.0 | 10.0~13.5 | A3BC-40180 | ||||||||

| 20.0 | 11.0~15.5 | A3BC-40200 | ||||||||

| 4.8 | 8.0 | 2.0~3.5 | A3BC-48080 | 9.0 [+0/-0.5] | 1.5 | 2.7 | 27 | 2230 | 1690 | |

| [+0.08/-0.15] | 10.0 | 3.0~5.5 | A3BC-48100 | |||||||

| 12.0 | 5.0~7.5 | A3BC-48120 | ||||||||

| 4.9mm | 14.0 | 7.0~9.5 | A3BC-48140 | |||||||

| 16.0 | 8.0~11.5 | A3BC-48160 | ||||||||

| 18.0 | 10.0~13.5 | A3BC-48180 | ||||||||

| 20.0 | 11.0~15.0 | A3BC-48200 | ||||||||

| 25.0 | 15.0~19.0 | A3BC-48250 | ||||||||

| 30.0 | 19.0~24.0 | A3BC-48300 | ||||||||

| 5.0 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 8.0 | 2.0~3.5 | A3BC-50080 | 9.3 [+0/-0.8] | 1.6 | 2.7 | 27 | 2500 | 2000 | ||

| 10.0 | 3.0~5.5 | A3BC-50100 | ||||||||

| 12.0 | 5.0~7.5 | A3BC-50120 | ||||||||

| 14.0 | 7.0~9.5 | A3BC-50140 | ||||||||

| [+0.08/-0.15] | 16.0 | 8.0~11.5 | A3BC-50160 | |||||||

| 18.0 | 10.0~13.5 | A3BC-50180 | ||||||||

| 5.1mm | 20.0 | 11.0~15.0 | A3BC-50200 | |||||||

| 25.0 | 15.0~19.0 | A3BC-50250 | ||||||||

| 30.0 | 19.0~24.0 | A3BC-50300 | ||||||||

| 6.0 | 8.0 | 2.0~2.5 | A3BC-60080 | 11.0 [+0/-0.7] | 1.9 [+0/-0.4] | 3.3 | 31 | 3900 | 3000 | |

| 10.0 | 2.0~4.5 | A3BC-60100 | ||||||||

| 12.0 | 3.0~6.0 | A3BC-60120 | ||||||||

| 14.0 | 5.0~8.0 | A3BC-60140 | ||||||||

| 16.0 | 7.0~10.0 | A3BC-60160 | ||||||||

| [+0.08/-0.15] | 18.0 | 9.0~12.0 | A3BC-60180 | |||||||

| 22.0 | 13.0~16.0 | A3BC-60220 | ||||||||

| 6.1mm | 26.0 | 17.0~20.0 | A3BC-60260 | |||||||

| 30.0 | 20.0~23.5 | A3BC-60300 | ||||||||

| 33.0 | 23.0~26.5 | A3BC-60330 | ||||||||

| 35.0 | 23.5~28.0 | A3BC-60350 | ||||||||

| 6.4 | 10.0 | 2.5~4.0 | A3BC-64100 | 12.0 [+0/-0.7] | 2.0 [+0/-0.5] | 3.7 | 31 | 4100 | 3120 | |

| 12.0 | 3.5~6.0 | A3BC-64120 | ||||||||

| 15.0 | 6.0~8.5 | A3BC-64150 | ||||||||

| [+0.08/-0.15] | 18.0 | 9.0~11.5 | A3BC-64180 | |||||||

| 22.0 | 11.5~15.5 | A3BC-64220 | ||||||||

| 6.5mm | 26.0 | 15.0~19.0 | A3BC-64260 | |||||||

| 30.0 | 18.0~23.0 | A3BC-64300 | ||||||||

| 33.0 | 20.0~25.5 | A3BC-64330 | ||||||||

| D | L | Nietbereich | Produktcode | dk | k | dm | p | Widerstand gegen Zug | Schnittschutz | ||

| 3.2 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| [+0.08/-0.10] | 6.0 | 2.0~3.0 | A5BC-32060 | 6.0 [+0/-0.4] | 1.0 | 1.75 | 27 | 1100 | 750 | |

| 8.0 | 2.5~5.0 | A5BC-32080 | ||||||||

| 3.3mm | 10.0 | 4.5~7.0 | A5BC-32100 | |||||||

| 12.0 | 6.5~9.0 | A5BC-32120 | ||||||||

| 4.0 | 6.0 | 1.5~2.5 | A5BC-40060 | 7.5 [+0/-0.4] | 1.3 | 2.1 | 27 | 1800 | 1250 | |

| [+0.08/-0.15] | 8.0 | 1.5~4.0 | A5BC-40080 | |||||||

| 10.0 | 3.5~6.0 | A5BC-40100 | ||||||||

| 4.1mm | 12.0 | 5.5~8.0 | A5BC-40120 | |||||||

| 4.8 | 8.0 | 2.0~3.5 | A5BC-48080 | 9.0 [+0/-0.5] | 1.5 | 2.7 | 27 | 2600 | 1850 | |

| [+0.08/-0.15] | 10.0 | 3.0~5.5 | A5BC-48100 | |||||||

| 12.0 | 5.0~7.5 | A5BC-48120 | ||||||||

| 4.9mm | 14.0 | 7.0~9.5 | A5BC-48140 | |||||||

| 16.0 | 8.0~11.5 | A5BC-48160 | ||||||||

| 18.0 | 10.0~13.5 | A5BC-48180 | ||||||||

| 20.0 | 11.0~15.0 | A5BC-48200 | ||||||||

Standards:

Die von Xinyu zur Verfügung gestellten Aluminium-Edelstahl-Senkkopf-Öffnungs-Pumpennitten sind auf der Grundlage eines nationalen Standards abgeleitet, deren Produktion nach den Standards für Aluminium-Edelstahl-Senkkopf-Öffnungs-Pumpennitten durchgeführt wird, abhängig von den hohen und niedrigen Magnesiumgehalten, die verschiedenen Arten entsprechen;

1, im Einklang mit der nationalen Norm für Aluminium-Stahl-Senkkopf-Öffnung-Typ-Kernnitte und den entsprechenden internationalen Normen (ISO) wie folgt:

GB/T 12617.1-2006 Öffnungstyp Senkkopf Öffnungstyp Saugkornnaden 10, 11 (gleichwertig zu ISO 15977: 2002);

US-Standard IFI-114-2003 Break Mandrel Blind Rivets für Aluminium-Stahlkopföffnung;

Die deutsche Norm ist DIN7337-1991 Break Mandrel Blind Rivets, B-Kopfform;

4, Aluminium Edelstahl Kopf Öffnung Typ Pumpkern Niete wählbar Durchmesser Serie von 2.4, 3.2, 4.0, 4.8, 5.0, 6.0, 6.4, 8.0, siehe die Spezifikationen Parameter Tabelle;

Produktprüfung nach GB / T 3098.18-2004 (ISO14589: 2000), Leistungsindikator ist GB / T 3098.19-2004.

|

Materialien |

Serienname |

|

5052 (Aluminiumlegierung mit 2,5% Magnesium) Nieten und Edelstahlspitzen |

A2BC |

|

5154 (Aluminiumlegierung mit 3,5% Magnesium) Nieten und Edelstahl-Nagelkern |

A3BC |

|

5056 (Aluminiumlegierung mit Magnesiumgehalt von 5,0 %) Nieten und Edelstahl-Nagelkern |

A5BC |